Recycling is extremely beneficial for the environment since it reduces air and water pollution, conserves energy and natural resources, and reduces greenhouse gases.

The process of recycling plastic isn’t hard as manufacturing new plastic products. But, plastic recycling isn’t a piece of cake either. It involves great attention to detail and rigorous procedures. The process can take up to several months.

In this article, we will go over the six steps of recycling plastic.

1. Collection of Plastic

Gathering waste plastic products is the first step to recycling. During the initial stage of recycling plastic, volunteers and employees go around collecting waste plastic from public places, offices, and homes.

A lot of areas have designated collection sites where people can toss away their plastics. Public locations typically have recycling bins that easy collection of plastics for recyclers. These bins are different from regular waste bins. Often, dropping plastic waste into these bins comes with rewards.

2. Categorizing of Plastics

After the plastic has been collected, it is sent to facilities where it is separated according to type. Since plastics differ in use, thickness, color, and size, during this process, the plastic is sorted by recycling machines based on the properties that the material. This process is essential because it lets recyclers know which materials are involved and how they get recycled.

3. Washing

Once the plastics are sorted, the materials are washed to remove any impurities. These impurities include particles, glue dirt, and paper labels. This part of the process is crucial because any impurities left on the plastics can damage the new product.

4. Resizing and Shredding

Plastic can’t be recycled in its original form, and it needs to be resized to a form that can be recycled. For the plastic to be reduced into fragments, the materials are put into shredders.

Resizing helps identify parts like metal that recyclers failed to notice during the washing phase. Shredding also allows reprocessing of plastic to other materials besides plastic products.

5. Separation of Plastics

After the resizing and shredding part has been completed, the following step is to identify and separate the plastic materials. The plastic particles go through testing procedures to identify the quality and class of the plastic. Then, based on their features, they are separated for further processing.

For example, density is one of the qualities that is tested during this step. Recycles place the plastic particles into a container filled with water to establish their density. The particles that float are denser, while those that sink are less dense.

This step also identifies other qualities like melting point, color, and air classification of plastic materials. Once the identification process is finished, the plastic particles are separated and sent for further processing.

6. Compounding

The final step in plastic recycling is compounding. Another name for this process is extrusion. During this step, the plastic particles are transformed into materials that manufacturers can reproduce. Compounding involves melting and smashing plastic particles to create pellets.

At the end of this step, the processing of the pellets results in new products (both plastic and non-plastic). This final step also consumes the most energy and time.

Final Thoughts

Make sure that you sort your waste and leave the plastic at the recycling center. If we all integrate well-planned strategies for plastic recycling and reuse in our waste management approach, it will be a huge leap toward preserving our environment.

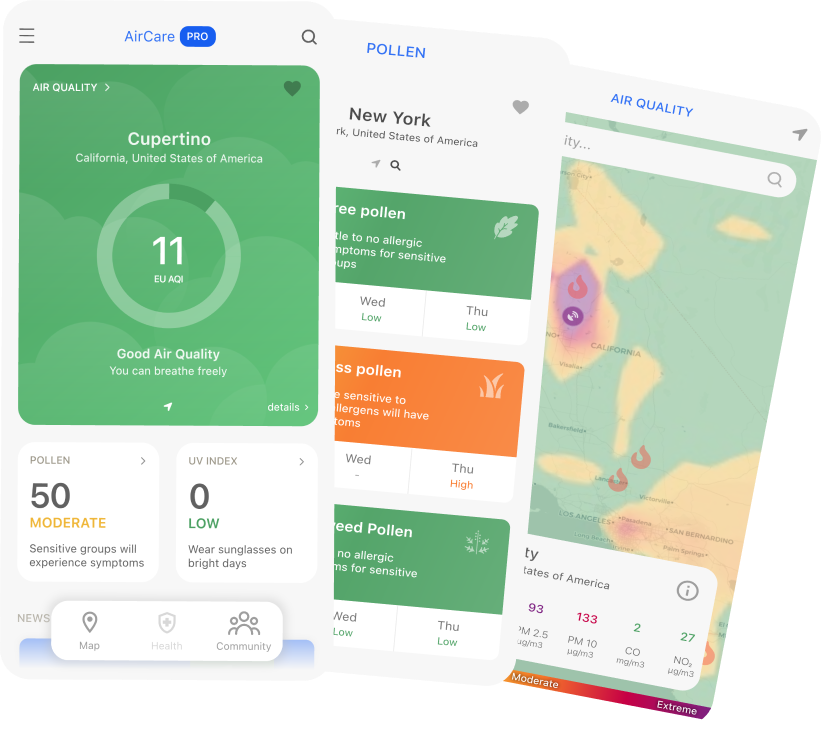

Do you want to know the quality of the air you breathe? Download AirCare – our free mobile app that tracks air pollution from your pocket, and check out the AirCare blog!